Market Insights

The fundamentals of water reuse

Questions to ponder before beginning a recovery process

November 16, 2012

Stability, growth forecasted for wine industry

Research shows demographic possibilities

February 15, 2012

Brewing a successful partnership

Stretch-wrap process saves distributor time, money

January 16, 2012

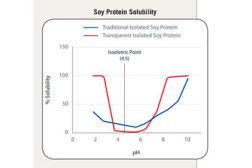

Processing low pH protein-fortified beverages

Comparing traditional soy with new transparent soy protein

December 13, 2011

Integrating LEED in design

Lighting solution suits environment, offers energy savings

October 14, 2011

LED lighting and strategy

Lighting solution suits environment, offers energy savings

September 12, 2011

Is green really better?

Determine if going green is right for your company

August 15, 2011

1881 finish: A global success story

New standard surface treatment unifies PET beverage packaging

August 15, 2011

Elevate your expertise in the beverage marketplace with unparalleled insights and connections.

Join thousands of beverage professionals today. Shouldn’t you know what they know?

JOIN NOW!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing