Packaging Equipment

Coding technology streamlines production line efficiency

Sustainability trends driving innovation for coding equipment

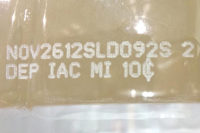

In 1844, Samuel F.B. Morse revolutionized long-distance messaging with the invention of the telegraph and Morse code. Used in maritime shipping and aviation, the system encodes text characters as standardized sequences of dots and dashes to transmit messages over a wire. Today’s coding technology also communicates by imprinting bar codes that reveal the freshness of a beverage with a “best if used by” date and more.

Advancements in coding and code application technology and scanning equipment has increased production speed, while eco-friendly inks have become the norm, says Ryan Petty, sector development manager for beverage at Domino Amjet, Gurnee, Ill.

“Continuous advances in technology mean production line speeds are rapidly increasing, resulting in higher numbers of cans being processed,” Petty says. “For example, a typical soft drink canning line is capable of running up to 2,000 cans per minute, all of which require codes. The coding system must be able to keep pace with these high production rates.

“The majority of codes are printed on the bottom of cans, where the surface is concave and therefore uneven,” he continues. “This challenge is exacerbated by the speed of the production line. Many manufacturers are trying to become vertically supplied, i.e., PET filling processes are taking their business from ‘pellet to pallet,’ meaning all plastic parts are made under one roof. Molding caps, bottle preforms, to blow-molding inline to the filler. Our coding processes are included in each of those processes. Many of our inkjet processes, whether on cans, plastic over wrap and carton coding, have been able to use our ethanol-based ink, which … has a quarter of the usage rate of MEK inks.”

Canada’s new requirements

As regulators look to protect consumers, America’s neighbors to the north are implementing new measures impacting coding technology.

Michael J. Orcutt, director of business development at Pittsburgh-based Matthews Marking Systems, notes that new Canadian coding regulations require more data. Additionally, the need for speed, and coding equipment that eliminates human error and physical touchpoints to improve efficiency and lower operating costs are trending in the industry, he says.

He explains that Canada’s new marking regulation contains more data to help consumers differentiate between individual foods and brands to make informed purchasing choices. “If it’s a fridge pack, there are a lot of people scrambling for products sold in Canada,” Orcutt says.

Although laser is the preferred method for coding, older lasers can’t keep up with the high rate of production speed and the detailed coding data required, he adds. There also are multiple marking technologies — each unique to a typical beverage plant — that are applied based on three code positions: primary, secondary or tertiary.

“On the primary package or container, the consumer is looking for a legible mark that can be read,” Orcutt says. “TIJ and Laser offers this capability, but many existing [thermal inkjet printers] (TIJ) printers drop in resolution at higher speeds … because they cannot process data fast enough, which is a controller based issue.”

To combat this issue, the company’s Matthews MPERIA controller and L-Series TIJ printers contain multiple head options to image the mark at faster speeds to improve production line efficiency through integration.

“[B]ecause of the complexity of data, especially for secondary marks, companies often need to move toward some type of ERP integration. This reduces human error and increases productivity,” Orcutt says. “Matthews can achieve this without using third-party software or any additional hardware. This is a win-win scenario for IT, as they don’t have to manage it and it doesn’t create a security risk.”

Depending on the type of packaging, including aluminum cans, PET bottles, blister packs, glass jars, cartons and flexible packs, small-character ink jet, laser and thermal transfer overprinters (TTO) printers quickly facilitate printing of marking codes, Domino Amjet’s Petty says.

For secondary packaging, which requires human- or machine-readable product identification, Domino Amject’s large-character ink jet printers are ideal for coding shelf-ready packaging such as fridge packs and shrink-wrap multipacks of cans and bottles, Petty says. The company also offers print-and-apply labelers for printing codes onto cardboard boxes, trays or plastic, he adds.

World of transparency

As consumers focus on health and wellness and scrutinize labels for ingredients, they’re also looking for the “best if used by” codes to ensure the freshness of products.

Domino Amjet’s Petty is seeing more marking details on bottles and cases. “[We’re seeing] more barcodes and traceable details that connect suppliers to packaging and have complete detail of the raw materials and the life span of them to finished goods,” he says.

Sustainability remains a hot-button topic, and the data coding supplier is seeing a distinct correlation between reliability and sustainability. “Domino understands how often minimal changes to eliminate rework will save on materials, energy, labor, handling, transportation — and ultimately, supports sustainability,” Petty explains.

Matthews Marking Systems’ Orcutt also highlights the importance of sustainability as the company manufactures its own ink, has its own sample marking lab to test inks, and can change ink formulations to best meet clients’ needs.

Orcutt urges companies to look at integration as a part of their marking and coding process. He says, “We have one CPG client that manages over 4,000 SKU’s a day … over 3 plants, 20-plus production lines and no one has to enter a code, that’s efficiency.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!