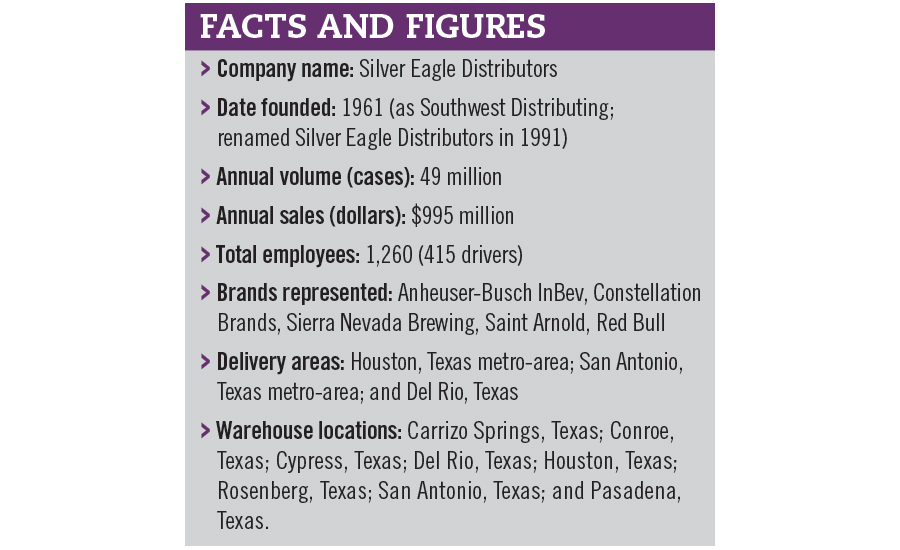

Silver Eagle embraces beverage fleet innovations

Texas-based beer wholesaler sees growth through change

It’s often said that change is the only absolute certainty in business. The difference between thriving, surviving or not, comes down to how one responds when those changes arrive, often at the least opportune moment.

When it comes to technological change, one school of thought says to wait and let others work out the bugs, while the other advocates for adopting new technology early to stay ahead of the curve. The massive pre-buy of diesel trucks in 2006 to avoid the headaches of newly mandated emission equipment on 2007 trucks is an example of the “wait-and-see” option.

At the opposite extreme, Houston-based Silver Eagle Distributors made its first move into the 2007-compliant technology in 2003, when much of the technology still was in development.

Silver Eagle’s Senior Vice President of Fleet Operations and Purchasing Ed Pritchard takes this proactive approach with new equipment and technology, whether it’s complying with the 2007/2010 emission regulations, being at the forefront of natural-gas engine adoption or expanding into new facilities. “For the most part, we try not to shy away from new technology,” Pritchard says. “Our [original equipment manufacturer] (OEM) suppliers have worked with our fleet operation to help smooth the transition and make sure our technicians are trained on the new engines.”

Sitting on 30 acres in Pasadena, Texas, with nearly 450,000 square feet, Silver Eagle’s newest and largest facility opened in 2014, dramatically enhancing the company’s inventory management processes and providing much-needed space to organize 1,800-plus SKUs daily. “It was definitely an investment aimed at providing superior service to a critical market area,” Pritchard says.

Pritchard and his team buck the trend toward full-service leasing, preferring to purchase most of their trucks outright and to perform maintenance in-house. “We are fairly well-connected with our OEM suppliers and their dealer networks, which, when combined with the Anheuser-Busch purchasing program, offers us the ability to purchase replacement vehicles at the lowest possible price,” Pritchard says.

Six of Silver Eagle’s eight facilities include vehicle maintenance facilities. “We are extremely self-sufficient in that over 98 percent of our vehicle maintenance is performed in-house,” Pritchard says. “We take maintenance very seriously, addressing any issues before the vehicle is released for service.”

Silver Eagle heavily focuses on key maintenance items that directly affect its bottom line. “Tires and brakes are critical elements in our preventative maintenance program,” Pritchard says. “Proper alignment and tire pressure are essential for achieving maximum tire life, while brakes require regular inspections and adjustments to avoid accelerated maintenance costs.”

Recognizing the impact drivers can have on equipment costs, Silver Eagle also places a strong emphasis on its driver training process. “The company approaches each driver, regardless of past experience, as a new driver to our business. Training is conducted in a highly structured environment that ensures consistency of results,” says Robert Boblitt, president and chief operating officer of Silver Eagle.

Pritchard adds: “Each new driver is paired with a designated driver trainer (DDT), focusing on every aspect of handling Class 7/8 combination vehicles in both inner-city and rural settings. Once their CDL driving permit is secured, the candidate is assigned to a sales representative trainer (SRT), who is a senior route-delivery driver who has been trained to effectively mentor new driver candidates on every aspect of route delivery.”

Silver Eagle’s training includes choosing parking locations to avoid vehicle/property damages, as well as proper grooming, customer relations, product rotation, vehicle pre-trip/post-trip safety inspections, and proper end-of-day settlement procedures.

“While the training process is lengthy and intense, the reward is a driver that feels confident in their ability to operate safely and effectively when they are released to pull a route on their own for the first time,” Pritchard says. “We also reward our drivers with incentives if they go accident/incident free for a year. Over the past few years, we have seen a reduction of more than 25 percent in the number of preventable accidents.”

Pritchard highlights the constant change in beverage fleet operations. “It’s an interesting time to be in the beverage business,” Pritchard says. “We’ve witnessed the first load of beer delivered by an autonomous truck — I would have never imagined this when I first entered the industry in 1981.

“There are new aspects of fleet management that require managers to rethink how they deal with ever more complex regulations, the rapid pace of advancements in emerging technologies, along with the constant challenge of training and staffing for technicians and drivers,” Pritchard continues.

He also offers advice for others in this sector: “Stay informed with what’s trending in the industry, not everything works for everyone. Stay connected with your peers and be flexible in your planning and thought processes. Occasionally, we need to recognize when a change of course is needed. Come to terms with the idea that you’ll never know everything and you’re going to need some help along the way.” BI

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!