Home » palletizers

Articles Tagged with ''palletizers''

Tradeshow features beverage product innovations, processing and packaging technologies

Read More

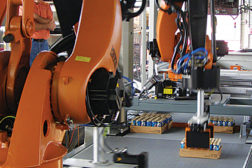

Robotics are adapting to meet beverage needs

Line speeds, flexibility key factors for robots

September 16, 2015

Benefits of depalletizers, palletizers

Automation drives operations with palletizers

July 16, 2015

Flexible, gentle palletizing, depallitizing equipment in demand

Automation of process offers big benefits

July 16, 2015

Palletizer automation helps fuel craft beer growth

Robotic, hybrid and conventional options help handle different packaging types

July 16, 2014

The happy, hybrid palletizer medium

Robotic, conventional palletizers offer differing benefits

July 15, 2013

Palletizers adapt to product evolutions

Advancements stay in step with SKU proliferation

August 12, 2012

Elevate your expertise in the beverage marketplace with unparalleled insights and connections.

Join thousands of beverage professionals today. Shouldn’t you know what they know?

JOIN NOW!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing