Home » palletizers

Articles Tagged with ''palletizers''

Rise in co-packing and sustainability goals impact equipment

Read More

Operations

Palletizers, depalletizers serve crucial role in automation’s future in beverages

July 10, 2023

Robotic palletizers, depalletizers enhance worker safety, increase efficiency

Craft beer, energy drinks driving need for automated palletizing operations

June 30, 2022

Operations

Palletizing equipment evolves to support lighter packaging materials

Adoption of robotics drives innovation within palletizing, depalletizing market

June 22, 2021

Operations

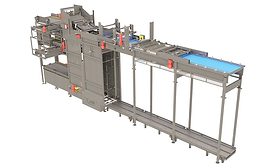

Automated palletizer systems optimize manufacturing, save time

Increased efficiency, space utilization improve operations

June 26, 2020

Supplier's News

Spa Springs provides co-packing, labeling and palletizing services for beverage companies

April 12, 2020

Emerson, Arrowhead Systems create machine health monitoring solution

Real-time solution brings data together for accessibility, visualization and analysis

December 11, 2019

Elevate your expertise in the beverage marketplace with unparalleled insights and connections.

Join thousands of beverage professionals today. Shouldn’t you know what they know?

JOIN NOW!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing