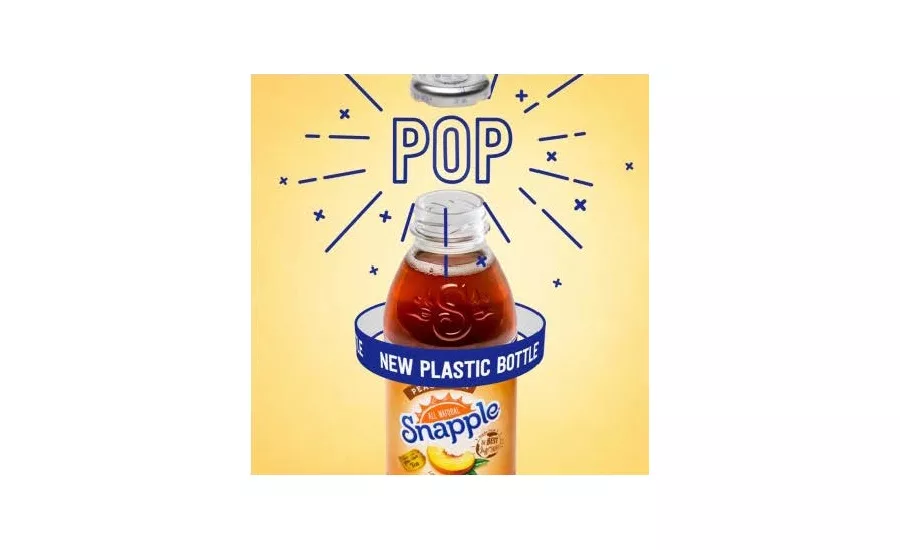

Snapple releases PET version of iconic glass bottle

Brand overcomes design challenges

Snapple released new PET versions of its iconic glass bottle. However, when the brand decided it was time to make the change, it was faced with a dilemma: How could it give on-the-go consumers the best possible packaging while still maintaining the Snapple look, feel and branding that its fans have come to expect?

In order to provide consumers with the experience they expect, the brand developed a new process, which focused on an important part of the Snapple experience: the satisfying “pop” that consumers hear when opening a bottle of Snapple. The sound that’s made when the tamper indicator releases is expected with each Snapple glass bottle but proved much trickier with its PET counterpart, the company says.

The key was getting the vacuum just right, it says. The challenge lay in figuring out how to generate enough of it for the metal lid to safely seal the bottle and provide the “pop,” but not so much that it deformed the plastic bottle. Cracking the code on the feature became an obsession for the DPS packaging engineering team, it adds.

“That's the No. 1 thing we had to solve that hadn't been solved before,” said Patrick George, senior director of manufacturing engineering, in a statement. “No one has done a metal closure on a PET bottle like this.”

According to Stephen Doerr, director of packaging engineering, the feat required “a solid six months of just the concept development work.”

Much of that work took place at DPS’s pilot plant in Irving, Texas, where plant manager Mike Burns was instrumental in completing this testing. The test facility is configured in the same way as one of the production plants, albeit on a smaller scale. It allows the DPS engineering team to give new products and processes a dry run before rolling them out broadly, it says.

Because the Snapple PET bottles are being phased into the marketplace, plants needed to be able to easily handle production of both the traditional glass bottles and the PET bottles. The new bottles also had to be compatible with vending machines, it adds.

“Anybody can design one of these [bottles] to work once,” said Doerr. “Once we had proven that the concept could work, we had to ensure it worked consistently. Michael Doerner, a senior manufacturing engineer, has played a critical role in rolling out the PET conversion project to our plants.”

The team faced another challenge: The aesthetic had to be just right, in keeping with its goal to give customers a consistent Snapple experience, the company says. From the shape to the embossed “S,” the PET bottle has the appearance of the familiar glass bottle, but with only one-fifth of the weight, it adds.

And that portability was another key consideration for the brand team, according to Noorin Sidi, brand manager for Snapple.

“PET is the fastest-growing package type in the tea category. It’s what our consumer wants and expects, and it opens Snapple up to more consumption occasions,” Sidi said. “Given their lighter weight and durability, the PET bottles are more convenient for consumers to take on the go and, of course, they’re less breakable. More importantly, they deliver the same great Snapple experience that consumers know and love from the pop of the cap to the last sip.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!