Suppliers release products to improve beverage production

Regal’s dry-running conveyor system saves on water costs

Canning it right

KHS USA announced the release of a new, compact can filler designed to meet the needs of small- to medium-sized brewing companies with an output between 10,000 and 48,000 cans an hour. The Innofill CAN Compact features fast product and format changeovers and combines filler and seaming operations in a compact plug-and-play design, it says. The new, scaled-down machine builds on the company’s Innofill Can DVD series, which was developed in 2014 for large-capacity operations. The Innofill CAN Compact features an efficient carbon dioxide purging system with low oxygen pickup and about 30 percent less carbon dioxide consumption than conventional systems, the company says. The hygienic system is easy to install because the filler, seamer, control cabinet, valve manifold and paneling are combined in a closed unit, the company says. Other features include a gapless bell guide with PTFE expansion joints and bells that are lifted and electro-pneumatically positioned so that cans are sealed without any mechanical action from cams and rollers, eliminating the need for water lubrication and providing easy maintenance. Because PTFE materials are used in the filling valve to seal the filling valve piston and in the gas membranes, flavor carryover during changeovers are eliminated, which helps craft brewers who often brew a large number of different beers and mixed beer beverages maintain consistency, it adds. The bell enables can necks from 200 to 206 to be processed while the product tank, which is installed at the top of the filler carousel, has a working volume of 50 to 200 liters.

KHS USA, 880 Bahcall Court,

Waukesha, Wis. 53186; 262/797-7200; khs.com.

Continuous loop

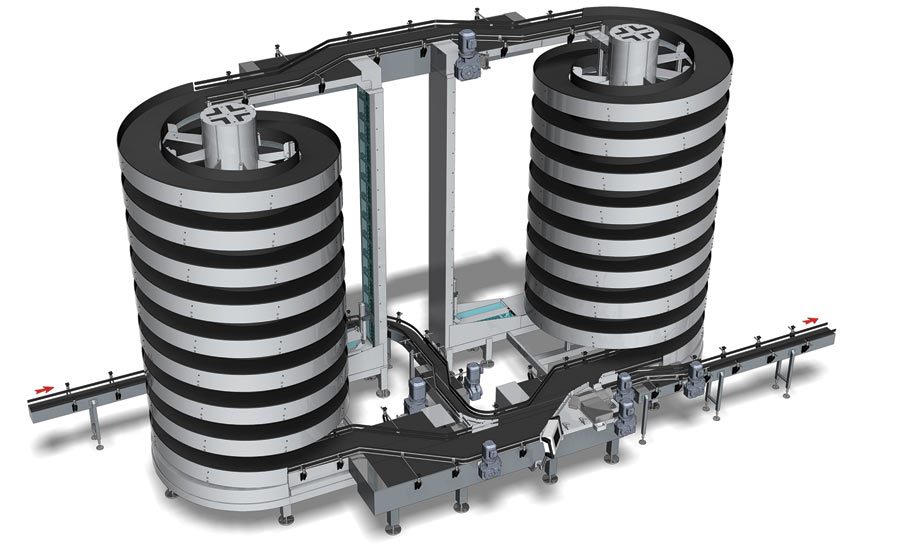

At Pack Expo in Las Vegas, Ryson International Inc. and Garvey Corp. introduced a new version of their patented continuous Infinity Accumulation Loop, which integrates two mass-flow spiral conveyors from Ryson with a patented infinity loop from Garvey to increase the use of available vertical space and system capacity within a small footprint. The Garvey Infinity uses patented technology to accumulate and single file even the most unstable of products at top speeds, and its loop technology efficiently handles products with no back pressure, breakage or label damage and with minimal noise. The reliable, low-maintenance Ryson Mass Flow Spirals can handle full or empty bottles, cans, jars and other types of containers in either an up-and-down single file or in continuous mass flow.

Ryson International Inc., 300 Newsome Drive,

Yorktown, Va. 23692; 757/898-1530; ryson.com.

Lubricating conveyor belts

At drinktec, Klüber Lubrication North America LP showcased its range of specialty lubricants and services, including its new Klüberplus C2 Dry series, which combines the advantages of conventional wet and dry lubricants while minimizing the generation of deposits on plastic conveyor belts, it says. Because the lubricants are NSF H1 and free of perfluorinated substances, they meet the requirements for the transport of carton packages, PET bottles and metal cans. The Klüberplus C2 series also lubricates all critical friction points on a conveyor belt and reduces friction between the conveyor belt and the container while supporting production plants in meeting workplace safety goals and hygienic standards. To help users in the beverage industry save energy and avoid downtime, Klüber also unveiled EfficiencyManager, a software program designed to foster transparent process planning in preparation for Industry 4.0.

Klüber Lubrication North America LP, 32 Industrial Drive,

Londonderry, N.H. 03053; 603/647-4101; klueber.com.

Measuring can seams

Wilkens-Anderson Co. offers its SEAM360 as part of its line of quality-control equipment for cans. The SEAM360 is designed to improve speed and accuracy while eliminating human error and misinterpretation, the company says. Conventional seam inspection occurs at two or three points around a can, but the SEAM360 scans the entire circumference of the can in approximately eight seconds while simultaneously measuring seam thickness and seam height at 360 points to a 0.0002-inch resolution, it adds. The non-destructive SEAM360 quickly and expertly detects any can defects, such as false seams, seam bumps, broken chucks, droops, vees and knocked down flanges, the company says.

Wilkens-Anderson Co., 4525 W. Division St.,

Chicago, Ill. 60651; 773/384-4433; wacolab.com.

Optimizing operations

Rexnord announced the release of its 1040 Series Magnetflex TableTop Chain and 1001-84mm Series MatTop Chain, which are designed to optimize operations and improve container handling for high-speed beverage conveying applications, the company says. The Magnetflex TableTop Chain offers a conveying chain solution for single-track, mass side-flexing conveying applications. Other features include a chain weight that is 40 percent lower than competitors, lower head shaft tension used to drive the chain for increased energy savings and a patented pin-retention solution. Designed for high-speed, single-track critical conveying applications, such as pressure-less combiners and de-combiners, the MatTop Chain provides increased optimization for each pitch throughout the conveyor length and improved sliding surface due to the no-clip-on-top surface. Both chains feature 0.2-mm height difference on top plates, allowing for high performance with excellent flatness along with flush grid execution to ensure that fluids and contaminants do not remain on the chain surface.

Rexnord, 4701 W. Greenfield Ave.,

Milwaukee, Wis. 53214; 414/643-3000; rexnord.com.

High-performance separator

At drinktec, Flottweg showcased its new AC1200 separator and announced the launch of a new product line of high-performance separators for small- and mid-sized companies. Designed for the beer, fruit juice and wine industries, the separator offers excellent clarification performance and product yield in a compact, user-friendly design, the company says. It also is equipped with a patented Soft Shot discharge system for product-friendly, quiet discharge and a more directed focus into the separator bowl; individual process integration and parameterization to fulfill customer needs and on-site requirements; and high flexibility with minimal space requirements.

Flottweg SE, Industriestraße 6-8, 84137, Vilsbiburg Germany;

+011/49-8741-301-0; flottweg.com.

Next-generation pricing technology

Vistaar Technologies Inc., a provider of pricing and promotion software for the beverage alcohol industry, offers the Vistaar Price and Reimbursement Platform (VPRP) to help companies with complete end-to-end price planning and reimbursement. The solution, which includes automation of downstream reimbursement calculations and distributor settlement for all forms of price support, outlines the financial impact of price changes throughout the supplier-distributor-retailer value chain, it says. Offering next-generation price technology, VPRP seamlessly automates price planning, reimbursement calculations and cash settlement into one closed-loop process. The software company currently prices more than 65 percent of all premium spirits and 45 percent of all wine sold in the United States, it adds.

Vistaar Technologies Inc., 14 Walsh Drive, Suite 200,

Parsippany, N.J. 07054; 973/581-6300; vistaar.com.

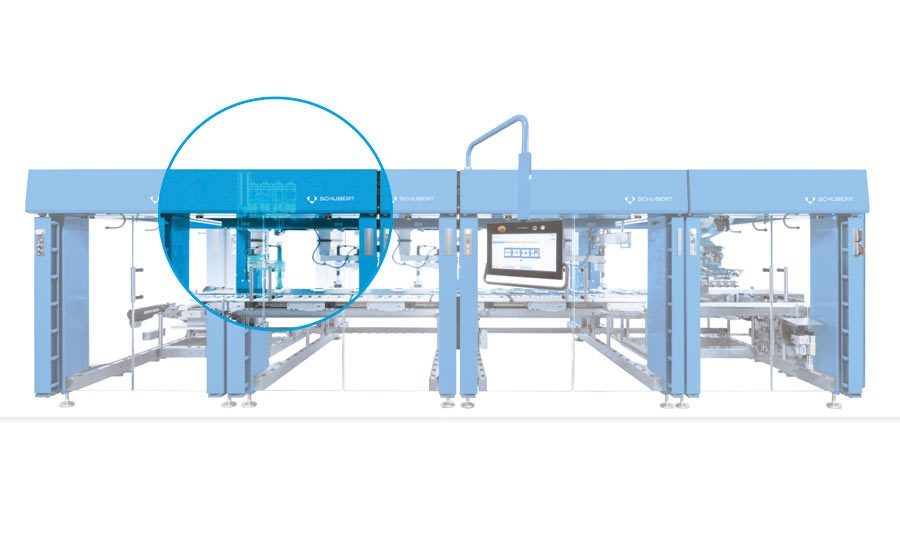

Packaging processes

At Pack Expo in Las Vegas, Gerhard Schubert GmbH showcased the flexibility of its high-performance technology using a picker line integrated with Flowmodul, a compact flow-wrapping component that efficiently packs products in flowpacks. The Flowmodul enables image recognition for quality control, pick-and-place robots, and packaging of flowpacks to come together in a compact, versatile system, the company says. The system’s entire operation is achieved via a single sleek and simple control module that achieves record-level performance in packaging a wide variety of products, it adds. It also highlighted its GRIPS.world digital platform and applications for preventive maintenance along with its primary packaging processes, such as the filling and sealing of coffee capsules, which can be seamlessly incorporated within the company’s TLM systems, it says. Tradeshow visitors also had the opportunity to use virtual reality to experience the potential of GRIPS.world. Additionally, it displayed a picker line with five F5 robots.

Gerhard Schubert GmbH, Industriegebiet Südost Hofäckerstraße 74564 Crailsheim, Germany;

+011/49-7951-400-0; gerhard-schubert.com.

Customized digital promotions

SIG Combibloc Inc. introduced a digital solution that provides total control of the production process while creating tailored digital marketing actions focused on the end consumer. The portfolio ensures 100 percent connectivity and transparency within the field of carton packs and filling technology. Born from the need of customers to meet new consumer demands and to prove the origin and quality of products, the solution gives food and beverage manufacturers the tools they need to maximize efficiency, reduce losses, maintain control of the product throughout the supply chain and showcase the quality of the final product, it says. The technology also enables consumers to better connect with a brand through the company’s first application for digital promotions — Promo-Clicks — which gives manufacturers the ability to use quick-response codes and geolocation tools to identify regions with high consumption while ensuring traceability and management of all production steps.

SIG Combibloc Inc., 2501 Seaport Drive,

Chester, Pa., 19013; 610/546-4200; sig.biz.

Speedy printing

Toshiba America Business Solutions Inc. announced the availability of its high-speed

(12 inches a second) B-EX6 thermal barcode printers, which are equipped to handle printing labels as large as six inches for manufacturing, supply chain and logistics professionals. The B-EX6 series features the company’s proprietary Ribbon Save1 technology for optimal ribbon consumption and reduced waste. Additionally, the large-capacity ribbon lessens the need for frequent media replacement, and the dual-motor system improves media handling while assuring the printing of scan-able labels, it says. The B-EX6 combines the latest in barcode-printer technology with advanced design, while its print heads are backed by a 3 million linear-inch warranty.

Toshiba America Business Solutions Inc., 9740 Irvine Blvd.,

Irvine, Calif. 92618; 949/462-6000; business.toshiba.com.

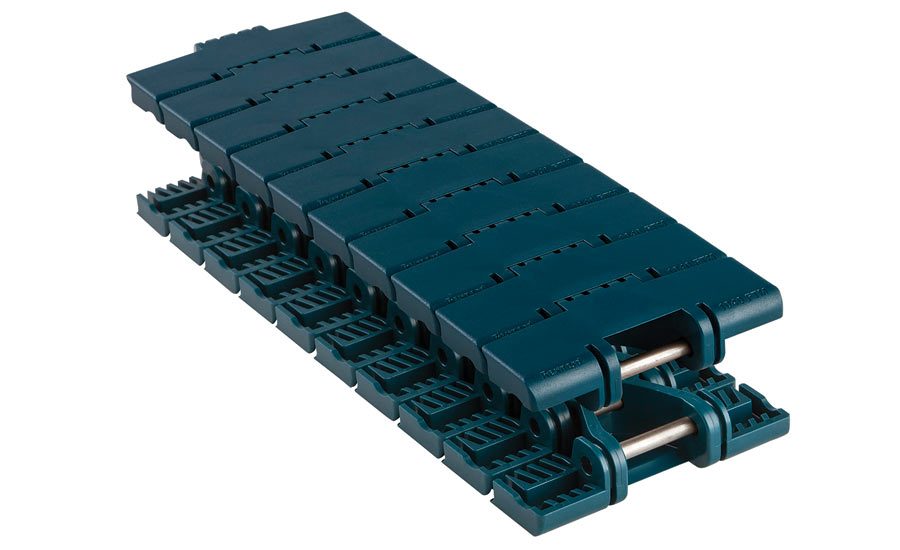

Saving water

Regal Beloit Corp. now offers System Plast NG Evo technology, a dry-running conveyor system that runs without lubrication or water. The system helps companies save as much as 750,000 gallons of water annually on keg lines, it says. Since the System Plast Dry Running Conveyor System was installed at Sierra Nevada Brewery 16 months ago, the brewery has saved 1 million gallons of water and has helped the brewery meet productivity and sustainability goals because the line runs without the use of water, soap or dry lubricants, it says. In addition to reducing component maintenance, the System Plast NG Evo conveyor chain is a low-friction, FDA-approved material designed for running dry conveyors in food and beverage applications. The thermoplastic design also can eliminate or greatly reduce wasteful water-and-soap lubrication, slip hazards, and the premature failure of bearings, gearboxes and other conveyor components typically seen in washdown conveyors.

Regal Beloit Corp., 200 State St.,

Beloit, Wis. 53511; 608/364-8800; regalbeloit.com.

On-shelf standout

At drinktec, UNITED CAPS Luxembourg S.A., a global reference for the design of high-performance plastic caps and closures, showcased its full range of off-the-shelf and bespoke beverage caps and closure solutions. With 75 years of expertise with plastics, the company’s “Less is More” approach is designed to deliver improved performance on bottling lines and with consumers, it says. Among the capping solutions it highlighted at the tradeshow was its new 26 FLAT Premium developed in anticipation of the new 26/22 CETIE neck. The 26 FLAT Premium is a lightweight mono-piece screw closure engineered from organoleptic resin. For increased safety, it includes an optimized venting feature and a slitted flexband that breaks after the first opening, providing reliable tamper evidence and assurance of product integrity, it says. Also made from organoleptic resin, the new 28 CC Flex cap was engineered to meet demanding carbonated soft drink specifications for high carbonation. The lightweight mono-piece screw-closure is fully compatible with existing 28-1881 closures and can be used for a wide range of applications, from still water to carbonated soft drinks with as much as 9 grams of carbon dioxide in a liter. The company also highlighted its Watwiller Flower Cap, which is targeted to older consumers and features a patented petal-flower design that allows the end-user to open a product with very little effort.

UNITED CAPS Luxembourg S.A., ZI de Wiltz, BP 49 9501 Wiltz, Grand-Duchy of Luxembourg;

+011/352-95-05-50; unitedcaps.com.

Simplifying product handling

At drinktec, Gebo Cermex showcased AQFlex, an intelligent, all-in-one product handling solution that offers a new approach to conveying and accumulation while delivering unprecedented packaging line performance, the company says. AQFlex offers agility and smooth, contactless product conveying and accumulation in a compact design that brings the factory of the future to life, it says. The new solution accommodates any product, any application and is available for all container materials, formats and shapes, full or empty, while also enabling automatic changeovers via an intuitive and user-friendly human-machine interface. The single-lane product handling and accumulation system operates at speeds ranging from 1,000 to 100,000 containers an hour, delivering an energy savings of as much as 60 percent without compromising efficiency or sustainability. All of the conveying functions of AQFlex, including contactless accumulation and multilane machine infeed, are regrouped into a single, universal-handling solution carried out as a single-file process, eliminating deceleration, degrouping, combining and laning. The centralized system architecture, which uses advanced robotics based on a proven logic motion technology, ensures the accurate synchronization of motion control for all of the servo axes. It also provides greater product traceability and continuous control of production quality based on a first-in, first-out operating principle.

Gebo Cermex, 5-7 Rue du Commerce, 67116 Reichstett, France;

011/33-388-183-850; gebocermex.com.

High-speed turning

Columbia Machine Inc. recently introduced its patented variable position turner (VPT) technology for applications using drop-down cushioned turners, the company says. The VPT technology maximizes speed and flexibility for in-line, high-speed palletizing by using servos to dynamically position the center turners laterally on the in-line palletizer while the layer is being formed. VPT locations are accessed and programmed via a human-machine interface, enabling the operator to easily create new layer pattern additions or optimize existing patterns. Fewer turners, a maximum of four, are required, and when used in conjunction with the company’s adjustable lane position technology, pattern forming capability is virtually limitless, it says. The VPT is ideally suited for ultra-high speed applications handling fridge packs, cartons, trays, film-only packages and more, it adds.

Columbia Machine Inc., 107 Grand Blvd.,

Vancouver, Wash. 98661; 800/628-4065; palletizing.com.

A cool breeze

Big Ass Solutions, the maker of Big Ass Fans and Big Ass Lights, debuted its first automated directional fan, AirEye. The first fan of its kind to detect motion and to automatically shut off, AirEye is quiet, long lasting, easy to clean and offers high efficiency, the company says. Other features include a motion sensor that ensures that the fan only operates when workers are present, saving energy during shift changes, breaks and shutdowns; a system that moves as much as 48 percent more air than other fans and creates a breeze a third of a football field away; patented airfoils that produce less noise even when the fan is operating at full speed; an electronically commutated motor that operates 50 percent more efficiently than typical directional fans; and standard infinite speed control that allows the fan to operate at 1 to 100 percent of full speed, rather than the typical two to three settings. Because AirEye is protected by an epoxy-sealed and powder-coated cage, the device’s hub and airfoils can endure years of daily use, and the easy-to-remove cage and components foster easy cleaning of dust and dirt buildup, it adds. AirEye is available with a variety of mounts, including I-beam, C-channel, wall, swivel and portable pedestal and comes in 20-, 24- and 30-inch diameters. The product has a seven-year, full warranty, it says.

Big Ass Solutions, 2348 Innovation Drive,

Lexington, Ky. 40511; 877/244-3267; bigasssolutions.com.

Capping it right

Adding to its portfolio of polyethylene (PE) resins, Dow Packaging and Specialty Plastics unveiled new EVERCAP PE resins that are designed for rigid caps and closures used in food and beverage packaging, the company says. The new caps address emerging mega trends, such as an aging global population and the need for more sustainable packaging options. Features of the EVERCAP PE resins include environmental stress crack resistance, stiffness and toughness as well as seal-ability, barrier production, durability, security, sensory characteristics, lightweighting and recyclability. The differentiated materials also offer excellent process-ability, with many drop-in solutions for use in existing compression and injection molding equipment, it adds. The caps also address senior dexterity limitations through easier open and close functionality; deliver sustainability improvements through material reduction, lightweighting and extended shelf-life; ensure health and wellness through both aseptic and hot-fill sterilization processes; and offer enhanced product safety with consistent, reliable tamper evidence. Working with the EVERCAP product portfolio also enables companies the ability to access Dow’s innovation methodology, including Pack Studios, which provides a global network of technical experts, equipment and testing capabilities that enable accelerated application development with collaboration throughout the value chain, it adds.

Dow Packaging and Specialty Plastics, The Dow Chemical Co., 1254 Enclave Parkway,

Houston, Texas 77077; 800/331-6451; dow.com/en-us.

Stylish wine refrigeration

Vinotemp now offers the Private Reserve Series 300-Bottle Commercial Wine Cooler featuring patent-pending adjustable wine racks, which gently cradle bottles to ensure that the label is front-facing, along with patent-pending interior light-emitting diode (LED) options in three colors: soft white, amber and Vinotemp BioBlu, which help reduce the growth of bacteria and mold, the company says. Designed to add a new level of functionality and style to commercial wine storage environments, the large-capacity wine cooler is front vented and designed for built-in or freestanding installation at restaurants, hotels and other commercial locations to add proper storage for as many as 25 cases of wine. The new cooler also features a vibration-damping design to better protect its contents and is engineered for low energy consumption and low noise, it adds. Other features include patent-pending interior lighting that can be selected or turned off at any time; sturdy, stylish patent-pending stainless steel gliding wine racks; an adjustable, 23-degree temperature range between 41 and 64 degrees Fahrenheit, allowing users to select a customized storage and serving temperature for light or dark wines; and an easy-to-read digital LED temperature display to ensure wine is stored and served at the appropriate temperature, the company says.

Vinotemp, 16782 Von Karman Ave.,

Suite 15, Irvine, Calif. 92606; 800/777-8466; vinotemp.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!