Suppliers streamline processing, quality control operations

New equipment unveiled at drinktec

Self-contained packaging solution

At drinktec, during a joint tradeshow booth, Gerhard Schubert GmbH and KHS showcased the benefits of the Innopack-TLM block packaging system, which seamlessly combines a Schubert TLM packaging machine with a KHS packer, significantly increasing packaging quality and flexibility, the companies say. The Innopack-TLM can efficiently pack several different bottle and end-packaging formats into a compact, space-saving unit. The inline packaging system consists of five TLM sub-machines from Schubert and a machine section from KHS that are connected by a patented robot, the Transmodul, which transports the erected cartons into the KHS system and then conveys the cartons filled with bottles to the appropriate module for gluing and sealing. The system can pack beverage crates as well as baskets, clusters and other cardboard packaging, at an output as fast as 48,200 bottles an hour, 134 six-unit baskets, or 45 crates or cartons a minute, it says. The flexible, modular design and space-saving solution also can be adapted to different formats and product mixes.

Gerhard Schubert GmbH, Industriegebiet Südost Hofäckerstraße 74564 Crailsheim, Germany; +011/49-7951-400-0; gerhard-schubert.com.

Perfecting microbial detection

At drinktec, Pall Food & Beverage exhibited a range of innovative solutions to help manufacturers protect what matters, it says. These included the launch of a cold filtration system, the CFS NEO, which is designed to help brewers reduce energy and water consumption while obtaining better microbial safety and preserving nutritional values. The new system is an alternative to flash and tunnel pasteurization. The company also showcased new GeneDisc microbial detection methods and protocols for beer spoilers, wine spoilage yeasts and Alicyclobacillus, enabling results in two hours, it says. It also highlighted its range of DE-free solutions to help customers protect their brands. The range includes the SEITZ ZD sheets, the PROFi Craft cross-flow system for craft breweries and the Oenoflow FIT cross-flow system for wineries. Designed to bring a fresh approach to filtration for food and beverage manufacturers, the company also showcased its Imperium MSB Filter, which reduces the risk of microbial contamination and improves filtration costs; and the Compact Touch, a new touchscreen integrity test device to give assurance of filter performance.

Pall Food & Beverage, 25 Harbor Park Drive, Port Washington, N.Y. 11050; 516/484-3600; food-beverage.pall.com.

Dual functionality

At drinktec, Sacmi showcased a wide range of technological and plant engineering solutions to meet the needs of both bottlers and converters, it says. Among them was the debut of HEROLINE, which by means of a cap and preform buffer achieves total integration of plastic and bottling technologies upstream and downstream from the bottling process. The compact, efficient HeroBlock is an all-new quadblock that combines stretch-blow molding, filling, closing and labeling all in one machine. The world’s first cross-process platform, HEROLINE integrates two processes and gives converters the ability to move closer to bottling operations by using in-house manufacturing solutions, providing added value for both bottlers and converters, it says. The total elimination of conveying systems and intermediate stages allows process optimization for both efficiency and cost. Building on the success of its COLORA CAP unit for the digital printing of caps, Sacmi also highlighted a new digital label printing module, D-MATCH, for the customization of pre-printed labels without the difficulties that come with the installation of complex machines. Designed to directly print on labels in a roll-to-bottle process on bottles, the new solution allows customers to test all the advantages of digital customization with an affordable device that can be retrofitted and used on any bottle shape.

Sacmi, Via Selice Prov.le 17/a, 40026 Imola BO Italy; +011/39-0542-607-111; sacmi.com.

Measuring ammonia

CHEMetrics announced the release of four new eco-friendly ammonia water analysis kits that use the phenolic compound hydroxybenzyl alcohol (HBA) to measure ammonia in potable water, surface water, storm water, groundwater and wastewater, the company says. With a shorter analysis time and extended measurement range, the kits offer significant advantages compared with the ammonia (salicylate) test kits, it says. Using HBA reagents reduces the color development wait time from 15 to five minutes, and the company’s patented VACUettes Auto-Dilution Method eliminates the need for pipets and flasks. An extended range also is available for the Instrumental Vacu-vials test kit, with ranges of 0-3.00 to 0-60.0 ppm. Other advantages of the new kits include improved packaging of accessory solutions for easier use and reordering and a 66 percent reduction in analysis time. The mercury-free HBA reagents also benefit customers looking to eliminate the use of mercury in their facilities, it says.

CHEMetrics Inc., 4295 Catlett Road, Midland, Va. 22728; 800/356-3072; chemetrics.com.

Measuring can seams

Wilkens-Anderson Co. offers its SEAM360 as part of its line of quality-control equipment for cans. The SEAM360 is designed to improve speed and accuracy while eliminating human error and misinterpretation, the company says. Conventional seam inspection occurs at two or three points around a can, but the SEAM360 scans the entire circumference of the can in approximately eight seconds while simultaneously measuring seam thickness and seam height at 360 points to a 0.0002-inch resolution, it adds. The non-destructive SEAM360 quickly and expertly detects any can defects, such as false seams, seam bumps, broken chucks, droops, vees and knocked down flanges, the company says.

Wilkens-Anderson Co., 4525 W. Division St., Chicago, Ill. 60651; 773/384-4433; wacolab.com.

Simply retrofitted

KHS announced that faster changeovers on the InnoPET Blomax Series IV stretch blow molder can be achieved by using optimized active mandrels, which have retained the company’s tried-and-tested design and currently are in use in the market, the company says. In addition to fast conveying mandrel changeovers that reduce changeover time by more than half for all standard neck designs, the new mandrels are ideal for beverage producers that bottle products with different types of necks. The new mandrel heads streamline operations because the typical high-performance Blomax stretch-blow-molder can have approximately 280 conveying mandrels that each need to be exchanged during format changeovers. The new options improve the line by offering an easy-to-replace variant, making changeovers ergonomic and tool free. In addition to the conveying mandrels, other components like shields and grippers easily can be switched using quick-change mechanisms that, in some cases, can be adjusted without installation by simply rotating the part, it says. Following a one-time adjustment of the conveying mandrels, no additional mechanical or electrical conversion is needed.

KHS USA, 880 Bahcall Court, Waukesha, Wis. 53186; 262/797-7200; khs.com.

Pressure steaming

Spirax Sarco Inc. now offers its Steam Jet Thermocompressor, an energy-saving device designed to compress low-pressure steam, often waste steam, to a higher, acceptable pressure, it says. The compact, lightweight design is easy to install into a pipeline including overhead installations. To ensure maximum operational efficiency, the thermocompressor is available in stainless steel, carbon steel, titanium, chrome and molybdenum. Because it does not have any moving or rotating parts and minimal maintenance is required, the units can be installed in remote or inaccessible locations. The Steam Jet Thermocompressor complies with the requirements of ASME B31.3 mechanical design standards, the company says.

Spirax Sarco Inc., 1150 Northpoint Blvd., Blythewood, S.C. 29016; 800/575-0394; spiraxsarco.com.

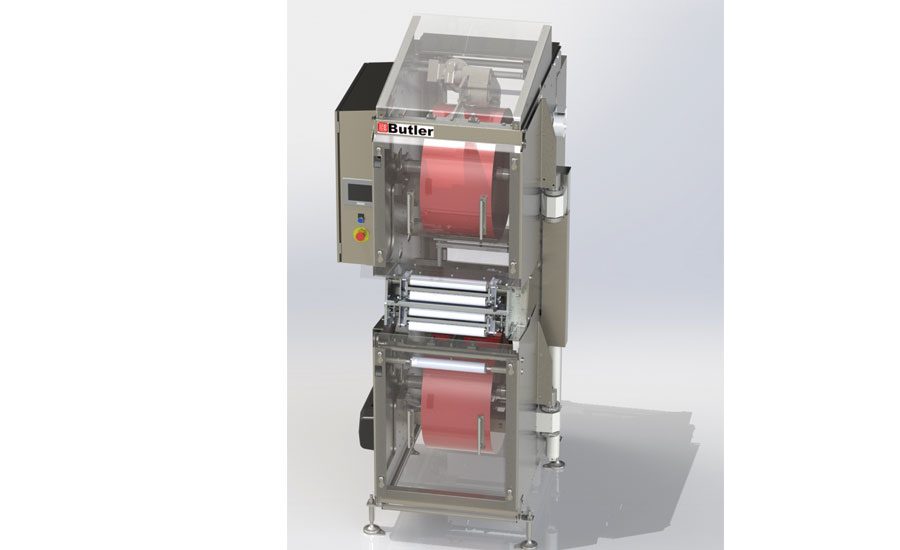

Splicing it right

Butler Automatic introduced an enhanced register sensor for new and existing SP1 Automatic Film Splicers that improves upon the previous sensor’s accuracy and reliability by featuring software that more precisely controls the splice position, thereby reducing packaging film waste, it says. Crucial for providing greater resolution and simpler control, the register sensor uses marks on the film to provide an automatic, in-registration butt splice. The splicer provides the downstream process with a consistent product pitch or imprint spacing, eliminating the need for re-registering the film after a splice. Additionally, the new sensor delivers a wider range of sensing and more reliability in distinguishing between similar colors and enables manufacturers to have print across the full width of the film, even when the print is similar in color to the black register marks. Although the prior design required operators to physically relocate the sensor in the in-web direction when adjusting between products of different length or pitch, the new control software allows the operator to achieve the same result by simply entering an offset value on the touchscreen user interface. The new register sensor is available as an option on any new Butler SP1 Automatic Splicer and can be retrofitted with any SP1 splicer.

Butler Automatic Inc., 41 Leona Drive, Middleborough, Mass. 02346; 508/923-0544; butlerautomatic.com.

Simplifying product handling

At drinktec, Gebo Cermex showcased AQFlex, an intelligent, all-in-one product handling solution that offers a new approach to conveying and accumulation while delivering unprecedented packaging line performance, the company says. AQFlex offers agility and smooth, contactless product conveying and accumulation in a compact design that brings the factory of the future to life, it says. The new solution accommodates any product, any application and is available for all container materials, formats and shapes, full or empty, while also enabling automatic changeovers via an intuitive and user-friendly human-machine interface. The single-lane product handling and accumulation system operates at speeds ranging from 1,000 to 100,000 containers an hour, delivering an energy savings of as much as 60 percent without compromising efficiency or sustainability. All of the conveying functions of AQFlex, including contactless accumulation and multilane machine infeed, are regrouped into a single, universal-handling solution carried out as a single-file process, eliminating deceleration, degrouping, combining and laning. The centralized system architecture, which uses advanced robotics based on a proven logic motion technology, ensures the accurate synchronization of motion control for all of the servo axes. It also provides greater product traceability and continuous control of production quality based on a first-in, first-out operating principle.

Gebo Cermex, 5-7 Rue du Commerce, 67116 Reichstett, France; 011/33-388-183-850; gebocermex.com.

Mixing made easy

At drinktec, KM Rustfri A/S launched a new valve for use in beverage production. The new valve enables beverage manufacturers to mix carbonated soft drinks and beers directly on the bottling line, leaving more tanks available for production and increasing output by as much as 300 percent, the company says. Part of the company’s Hydract system that was developed in 2008, the new valve gives manufacturers total control of the amount of fluids going upstream and downstream, ensuring that products in the bottling line can be safely mixed. With air valves in piping systems, a pressure of

10 to 12 bars is achieved, but the Rustfri valve uses water hydraulics, which can withstand a pressure of 50 bars, making it easier to control the amount of fluid going both downstream and upstream. Already in use in the zip lines at the Carlsberg Brewery in Denmark, the valve can be retrofitted into existing piping systems to increase capacity and final output because the tanks that normally are used for mixing can be used for other purposes, like fermentation.

KM Rustfri A/S, GL. Roenbjergvej 2a 7800 Skive, Denmark; +011/45-9753-4344; kmrustfri.dk.

An accumulator to ‘die’ for

Drilling Technical Services Inc. announced the release of a new, compact die-cut thin film blank accumulator made with a motion-control system from Siemens Industry Inc. The VR Series cut-and-stack accumulator utilizes motion-control products to efficiently transfer film blanks from the point of cutting to the precise positioning in a counted stack, it says. The accumulator processes thin film substrates, eliminates static and provides superior blank control throughout the process. It also converts blank shapes in multiple streams while integrating the equipment into continuous print-cut processes or offline converting systems. Recognizing the importance of the control scheme on the machine, the VR Series in-mold label accumulator integrates high-precision Sinamics drives and Simotion motion control along with Simotics servomotors and a touchscreen Simatic human-machine interface. The labeler accommodates unique blank shapes in one, two or three streams on a small-footprint machine capable of handling web widths between 13 and 26 inches. Additionally, the machine provides end-users with simple matrix separation while diverting scrap at the process start-up or as a component in the overall quality-inspection system. The machines also can create serialized groups through a bottom-up stack format with total static control.

Drilling Technical Services Inc., 6062 Kells Lane, Milford, Ohio 45150; 513/831-2952; drillingtechservices.com.

Clean water technology

GE Water & Process Technologies released BEVPAK, a new ultrafiltration (UF) and reverse osmosis (RO) solution for water treatment in the production of beverages. The product is designed to process poor quality and challenging source water while removing particulates, microorganisms and total dissolved solids, the company says. It incorporates ZeeWeed 700B horizontal-designed, inside-out UF membranes with the BEV Series RO technology, delivering beverage producers a distinctive product that provides quality, reliability, ease of operation and monitoring capabilities with simple installation. By combining UF and RO on a single skid, BEVPAK also reduces the plant footprint by as much as 30 percent compared with using the technologies separately. The following are other features of BEVPAK: a multi-barrier process with NSF-certified membrane elements to meet required product specifications; higher quality feed water to the RO, which improves reliability and increases the RO system uptime even with highly variable raw water quality; reduced chemical cleaning frequency and membrane replacement frequency caused by fouling; and simple installation with preconfigured pretreatment pumps, piping and electrical systems. Internet connectivity also allows remote monitoring, after-hours diagnostics and troubleshooting.

GE Water & Process Technologies, 4636 Somerton Road, Trevose, Pa. 19053; 215/355-3300; gewater.com.

Red light, green light

To take the guesswork out of the question “is the single-stall restroom occupied or not?,” the Heads-Up Lock Co. engineered a new, wireless solution designed to prevent inconvenient, even costly, trips due to waiting in line to use an occupied restroom, particularly if it’s located hundreds of feet away and/or out of sight, the company says. The user-friendly Heads-Up Lock displays a red or green light that can be clearly seen from distances as far as 200 feet. The patented, affordable device is hands-free and easily installed in all single-stall restrooms, helping to increase traffic flow in public venues including restaurants, coffee shops, office spaces, retirement homes and retail stores, it says.

Heads-Up Lock Co., 160 Arroyo Grande Way, Los Gatos, Calif. 95032; 408/966-4365; headsuplock.com.

An unbreakable bond

ACTEGA North America, a member of global specialty ink, coatings and sealants company ALTANA AG, announced the addition of its new RAD-BOND UV Laminating Adhesive line to its product portfolio for the labels market. The system is designed to laminate bi-axially oriented polypropylene film (BOPP) to BOPP and BOPP to paper, the company says. The laminating adhesive also provides increased press speeds with excellent bond strength and clarity and is ideal for any printer in the narrow-web label market that currently laminates because it offers superior adhesion with lower coat weights, it adds.

ACTEGA North America, 950 S. Chester Ave., Suite B2, Delran, N.J. 08075; 800/255-0021; actega.com.

A tough cube

Designed to fit a variety of applications and processes, Elkhart Plastics Inc. designed an Intermediate Bulk Container (IBC), known as the Tuff Cube, for the Canadian market, it says. Available in a 454-liter size, the Tuff Cube, a spin-off of the Tuff Stack, is made using high-quality, rotationally molded plastic components and offers a more affordable option than steel-cage IBC designs. Tuff Cube IBCs also can be stacked, washed and reused and are available in a variety of customizable options including food-safe and recyclable resins, a range of colors, and a variety of inset logo and labeling capabilities for both the Canadian and American markets, it adds.

Elkhart Plastics Inc., 3300 N. Kenmore, South Bend, Ind. 46628; 574/232-8066; epi-roto.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!