Robotics reduce downtime, handle repetitive tasks

Advances in machine vision, algorithms solve problems

“Danger, danger, Will Robinson” was a phrase that the robot frequently uttered to the youngest member of the Robinson family during the mid-1960s TV show “Lost in Space,” about a family whose spaceship crash lands on an alien planet. Although the robots in today’s beverage plants do not display human emotions, robotic systems increasingly are being used in beverage operations to speed up bottling, packing and distribution efforts.

Experts note that the use of robotic palletizing, robotic layer forming and robotic layer handling continues to permeate the beverage industry, particularly as companies that have never used automation start to recognize the far-reaching benefits of robotics. These include greater speed and efficiency; cost effectiveness; increased volume with less downtime; the ability to handle different product types, case sizes and pallet patterns with little or no manual changeover; and an ability to function in myriad environments, including freezers.

Increasingly, robotics are a go-to technology in packaging and palletizing operations, providing automatic assistance for stacking cases of goods or products onto a pallet, helping to eliminate the time-consuming, expensive and physically taxing process for workers of manually placing heavy boxes onto pallets, says Matt Wicks, vice president of product development in manufacturing systems at Intelligrated, Mason, Ohio.

“Many of the robotic technologies are actively evolving and/or are in the emerging state, and have yet to realize the promise … of a completely mature automation system,” Wicks says. “There are several tasks within the warehouse that are primed for robotic automation, such as item/each picking. … Leveraging automation and robotics also can help offset the challenges of maintaining a consistent, reliable workforce.”

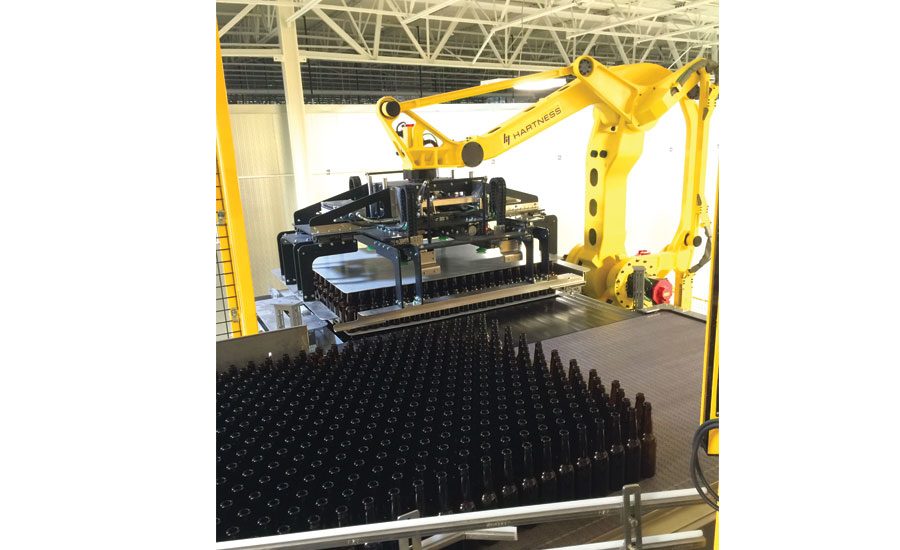

With the global palletizing equipment market targeted to grow at a compound annual growth rate of nearly 4 percent from 2016-2020, the installation of robotic palletizing systems instead of conventional palletizers will continue to climb, according to Matt Job, business unit manager at Hartness International, Greenville, S.C.

“Automated systems will increase their market share,” he explains. “The growing middle class in Asia Pacific means that a declining proportion of the population is willing to work for low wages. Rising salary expectations in certain countries may affect where investment is made in both new and existing facilities, as well as the use of robotics to keep labor costs low.

“In the developed world, the increased production demands and the need for greater flexibility to handle the ever-changing market demands is driving the implementation of more robotics in the packaging industry,” he continues. “Ease-of-use is a big trend, which is challenging robotics providers to invest in usability features. With reduced workforces, and more demand for greater line flexibility and throughput, equipment is getting more complex.”

Bob Doyle, director of communications for the Ann Arbor, Mich.-based Association for Advancing Automation (A3), expresses similar sentiments. “The biggest trend is the introduction and use of collaborative robots. These are robots working side-by-side with humans. We’re seeing companies who may have never utilized automation before take their first step by integrating collaborative robots,” he says. “… Typically they are cheaper and are faster to set up and integrate into a system. They also can take up much less floor space than a traditional industrial application.”

With collaborative robots, humans and robots easily can occupy the same workplace at the same time, but “safeguards and a risk assessment are required, in accordance with the robot system safety standard ISO 10218-1 and -2:2011,” Doyle says.

While the beverage industry has successfully used robotics in layer forming and handling operations for several years, the trend is moving toward robotic mixed case palletizing systems, says Bob Hoffman, director of consulting for food and beverage logistics, Swisslog Logistics Inc., Newport News, Va.

“While both single case and case group palletizing systems have had success, we will see the most transformation in the industry with multi-case 3-D palletizing of mixed orders,” he explains. “Today, there are very few sites utilizing this type of technology. The learning curve was slow as those in the industry sought to understand the algorithms and stacking rules needed to accommodate unlimited order profiles.”

Integrated, evolving technologies

Typically, beverage production lines require repetitive, consistent processes, and robotic systems, including multi-jointed articulated arm robots and the newer collaborative robots and mobile robots, provide durability, flexibility and accuracy on packaging lines, experts say.

Improvements in software also are furthering the use and performance of robotics, Intelligrated’s Wicks says. “Improvements in machine vision, advanced algorithms and sensing solutions are being integrated into sophisticated robotic solutions to solve automation problems that have never been solved before,” he says. “Newer software allows beverage manufacturers … to quickly and easily change their stacking patterns and configurations in palletizing operations.”

Advances in automotive, aerospace and manufacturing applications also have pushed advancements in vision technology, Swisslog’s Hoffman adds. “[T]hey are pushing the technology to a robust, competitive level. … But it takes an embedded culture that understands the technology, and if these complexities are not understood at each step, it can easily lead to a failure within the system,” he says.

Yet, when integrating robotic technology into the process, a clearly defined means of integration with other equipment is crucial. For example, Carlstadt, N.J.-based DMW&H offers mixed case palletizing with a four finger gripper.

“This special gripper with smart software allows for a nice increase beyond the current industry rates for mixed case palletizing,” DMW&H’s Vice President of Food and Beverage Paul Laman says. “The integration of vision technology into robotics has steadily been improving, especially as it pertains to a robot trying to pick individual cases off of a staged pallet. The robot needs vision to identify the case it is looking for.”

The beverage industry also is increasing its use of automated storage/retrieval systems (AS/RS) and automated guided vehicles (AGVs) to support the bottling, packing and warehouse storage aspects of the business.

“There is a trend to start incorporating more and more AS/RS,” Swisslog’s Hoffman says. “The typical Pareto Curve for beverage orders is approximately 80-20. With this type of distribution, deep draw storage systems like the Swisslog PowerStore AS/RS are the perfect fit for the application.”

An increasing number of SKUs also are ramping up the use of robotics in beverage warehouses. “[R]obotics, and the flexibility they bring, are able to scale up or down [depending on] the level of warehouse automation,” Hartness’ Job says. “From full layer handling to feed single case AS/RS systems, to more complex mixed load palletizing to build direct-to-store multi-SKU pallets, robotics are able to increase flexibility to help fully automate key functions in the warehouse.”

Also recognizing the evolving impact of robotics, Wes Garrett, authorized system integrator account manager for pick/pack/pal at FANUC America Corp., notes that the Rochester Hills, Mich.-based company introduced more than 10 new mechanical units in 2016. “From these new units, the beverage industry will benefit from a large 500-killogram (kg) palletizer to a full family of collaborative robots, and a fully enclosed 25-kg packing/material handling robot where it really opens the door to handle new applications,” he says.

“Manufacturers should expect to find a good return on investment, reduced downtime and expanded throughput,” Garrett continues. “Most important, automation offers safety to employees required to perform heavy lifting and repetitive tasks. … Our mean time between failures is at plus 100,000 hours.”

FANUC offers different types and styles of robots, including three families of Delta robots, which lend themselves to high-speed picking/tracking applications. Its full line of Serial Link robots provide 4- to 2300-kg payload. “Within this group are four- and five-axis robots that are well-suited for high-speed packing and palletizing, as well as six-axis models for all other applications requiring six degrees of freedom,” he says. “We also offer picking and palletizing software, IRPickTool and PalletToolTurbo, respectively, to minimize integration time and enable line-tracking applications.”

To expand its product portfolio and offerings, Swisslog acquired FORTE Industries and opened a beverage systems-focused field office in Charlotte, N.C., earlier this year. It also acquired Power Automation Systems (PAS), a supplier of pallet shuttle systems, it says.

Robust robot sales

With robotic technology expanding and improved software being developed, robot sales in different industries, including food and consumer goods, are up an average rate of 5 percent a year for the past five years, according to A3’s Doyle.

“A newer technology is the use of mobile autonomous robots. … These can be used to bring products and materials from point A to point B autonomously,” he says. “Robotics technology has the opportunity to solve countless operational problems. It makes companies more productive, which allows them to grow.”

However, some companies still have concerns about integrating robotics in their beverage plants. “Businesses are concerned they will invest large amounts of money and be marginally successful, while automation anxiety stems from the combination of the fear of automating being in conflict with the fear of not automating,” Swisslog’s Hoffman says. “The internal conflict is natural.

“… The best way to choose automation is to analyze the data and let the data drive your choice,” he continues. “Choose a ‘partner’ with a deep bench rather than a supplier. Too many times people see a shiny new tool and say, ‘I have to have that.’ The new tool may not even fit their need. The key is data analysis.”

The future of robotics technology is bright, experts say. “We will continue to see robotics technology integrated into existing lines and as a key part of new lines. The major drivers are the ability to simplify function while increasing throughput, reliability, accuracy and flexibility,” Hartness’ Job says. “Investing in automated equipment that can solve today’s problems while being ready to tackle tomorrow’s opportunities makes good sense for the fast-changing food and beverage industry.” BI

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!