F.X. Matt Brewing Co. adds equipment to maximize craft beer quality

Craft brewer plans to expand pilot brewery to promote craft beer experimentation

F.X. Matt Brewing Co.’s Utica, N.Y., brewery houses two 500-barrel copper brew kettles. (Photo by Susan Farley)

Most often running 12-ounce bottles, the bottling lines at F.X. Matt Brewing Co.’s Utica, N.Y., facility fill beverages at a rate of approximately 800 bottles a minute, says Chairman and Chief Executive Officer Nick Matt. (Photo by Susan Farley)

Upon entering the century-old F.X. Matt Brewing Co. offices in Utica, N.Y., visitors are greeted with Victorian-era furnishings, including an old bank teller counter with a slanted bottom to accommodate women’s hoop skirts. Historic furnishings like this continue throughout the 400,000-square-foot campus. However, despite its historical appearance, the facility offers many modern touches.

| Jump to: |

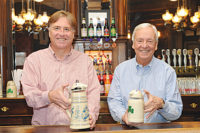

Wrapping up its 125th anniversary celebration this month, the company produced approximately 350,000 barrels of beer and 250,000 cases of carbonated soft drinks (CSDs) last year all from its Utica facility, according to Nick Matt, chairman and chief executive officer, and Fred Matt, president and chief operating officer. In addition to Saranac-branded CSDs, the brewery manufactures a lineup of beers under its flagship Saranac brand as well as its Utica Club, High Peaks and Lake Placid brands in addition to contract-produced beers. Its Saranac beers account for more than half of the company’s sales, while Utica Club makes up 5-10 percent of sales, Nick says. Contract brewing makes up one-third of its business, he adds.

Housing two bottling lines, one canning line and one kegging line, the facility can accommodate production of both beer and CSDs running only one shift, Nick says. In addition to sharing a bottling line, the beer and CSD products often share a distribution route as well.

F.X. Matt Brewing spans a distribution territory from Maine to Ohio and up from North Carolina, which accounts for approximately 45 percent of the U.S. population, Fred notes. Within this territory, nearly every beer account has an interest in CSDs, he says. Therefore, it typically uses a beer wholesaler to distribute its CSDs.

The CSDs also are convenient for F.X. Matt Brewing to make, because they don’t take up much space or time, Nick notes.

“The soft drinks are easier to make, because in terms of the beer, we have to brew it and age it and everything,” he says. “Soft drinks you don’t have to age at all; we just package them. So we get to use our bottling facilities without having to tie up fermenting and aging, and that’s always the place we have capacity constraints.”

The Utica facility currently houses more than 20 fermenting tanks, which typically hold beers for about a week, Nick says. Then the beers are aged in one of 78 aging tanks for two weeks, he adds. In order to add capacity where it is needed, F.X. Matt Brewing plans to build a new facility across the street to house additional fermenting and aging tanks, Nick says. The expansion would effectively add 50 percent more capacity for the brewery, he notes.

This year, the company hopes to increase its beer production by about 10 percent to 380,000 barrels, Nick and Fred say.

Experimental additions

Adding to this growth and innovation, F.X. Matt Brewing installed a pilot brewery with four 2-barrel tanks less than a year ago. It plans to add two more tanks to the pilot brewery in the near future, Nick says. This addition enables the company to experiment with unusual offerings on a smaller scale, which is what the craft beer movement is all about, he says.

As a result, the company currently is experimenting with a beer aged in whiskey barrels. It also plans to craft some unusual hard ciders, Nick says.

The pilot brewery also enables the company to experiment with specific ingredients to determine how they affect the overall flavor profile of the beer, Fred adds. For instance, it can brew a beer with only one type of hops to determine how that particular ingredient impacts the overall flavor profile of the beer, he explains.

Emphasis on quality

In addition to the flavor profile of the beverage, F.X. Matt Brewing’s full-scale laboratory enables analysis of all of its products to maintain quality, Nick adds. Every time a product is moved during the production process, it undergoes a series of analyses, he notes.

Three full-time employees, including a microbiologist and a chemist, as well as a supervisor work in the laboratory to ensure high quality, he says. The extent of F.X. Matt Brewing’s laboratory is rare for a brewer its size, Fred notes. However, the company’s commitment to quality has been the key to its survival for 125 years, so it will not compromise those values, he says.

To that point, the company made three investments within the last year to help enhance its products’ quality. The first is its invention of the Hop Injection Process. After an employee discovered that some of the hops in the beers were being left behind at the bottom of the tank, F.X. Matt Brewing developed a process to help retain those ingredients.

“We do a lot of dry-hopping in beer to give it a little more hop flavor, and we discovered that when we drained the tank, some of the hops didn’t look like they were actually getting up into the beer and doing what they were supposed to be doing,” Nick explains. “So we created [a process to], in effect, swirl the hops in while we’re filling the tank and use it to put the hops in liquid so that they’re in suspension when they go into the tank.” As a result, the beer ends up with a cleaner hop taste, he says.

In another instance, the company is in the process of investing in a decanter, which will increase its ability to add hops later in the process prior to fermenting to increase the aroma in hop-forward beers like pale ales and IPAs, Nick says.

Additionally, the company put in a new malt mill last year that allows it to process the malt, which it receives by railcar, more quickly and also makes the malt easier to cook by breaking through the husk, Nick says.

“It does it more uniformly so that, therefore, we end up with a better quality when we get to the mash cooker,” he says.

All of these investments demonstrate the company’s emphasis on continual improvement, Nick says.

Being green

Although F.X. Matt Brewing has spent much of its capital on equipment and processes that will help its products to be more innovative and high quality, it also continues to invest in sustainability.

In the interest of making use of its waste, the company sells the grain it filters out with a mash filter to local farms as feed for cows, Nick says.

It also makes use of waste as energy for its facility. Last fall, the company installed an anaerobic digester facility, which should eventually generate up to

40 percent of the company’s electrical needs, Nick says. It works by collecting the brewery’s wastewater and treating it through one of five anaerobic digesters, which reduces the biochemical oxygen demand in the wastewater by about 80 percent, he explains. This reduces stress on the city’s sewer system, and it also generates methane gas in the process, which can be used to run a generator, he says.

The company also has collected carbon dioxide from its brewing process for years, he notes.

“When you ferment the beer, you generate carbon dioxide, and we collect that carbon dioxide so we have to buy less,” Nick explains.

The brewery’s warehouse also boasts geothermal wells, which help with heating and cooling, he adds.

“We think it’s important, even in an older facility, to be doing the right thing in terms of the environment,” Nick says. Typically, sustainable improvements can be accomplished more easily by a company building from the ground up instead of one that’s more than 100 years old, the executives say, but it underscores F.X. Matt Brewing’s commitment to being green, nevertheless.

Ultimately, the company hopes to be “off the grid” one day, Fred says. “It’s probably years away, but you’ve got to have a goal.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!