Vertical integration to the max

Injection, blow molding put Admiral Beverage’s plants at the top of their game

One pound of resin makes 18 20-ounce bottles on one of Admiral Beverage’s two injection molding lines at its Ogden, Utah, production facility.

Cans of Mountain Dew Voltage pass through a fill level inspector in the Ogden, Utah, facility. If there isn’t enough liquid inside the can, it is rejected from the line

Being a trendsetter isn’t always ideal. You’re often the “guinea pig,” which could be a good thing or a bad thing. For Admiral Beverage Corporation, it’s a good thing. The company was one of the first bottlers in the country to install injection molding machines, it says. After introducing blow molding lines to both of its production facilities a few years ago, injection molding has enabled the business to become even more vertically integrated.

“Everything in the market today and in the past is about vertical integration,” says Clarence Foster, plant manager for the company’s Ogden, Utah, facility. “The more levels of vertical integration you have, the more profitable it is. So if you’re the bottler as well as the distributor, then you have two levels of profitability in your organization. And [by having injection and blow molding lines], that makes us vertically integrated in plastics.”

Admiral Beverage Corp. has two injection molding lines, which can make up to nine different bottle shapes, at its Ogden plant. All preforms are created at this facility and provide the entire supply for plastic bottles produced in the Ogden plant and at the company’s main production facility at its headquarters in Worland, Wyo. Both production facilities manufacture PepsiCo and Dr Pepper Snapple Group (DPS) brands; however, the Worland plant exclusively manufactures bottled water. The company’s warehouses at both locations store all of these products, including the MillerCoors brands offered through the company’s beer distribution business.

Innovation in Utah

In addition to its injection molding lines, the company’s 150,000-square-foot production facility in Ogden operates one blow molding line, one bottle line, one can line and one bag-in-box line. The bottle line produces 16.9-ounce, 20-ounce, 24-ounce, 1-liter and 2-liter PET bottles. It has the ability to fill as many as 500 bottles a minute; however, speeds can vary depending on package size and product. Likewise, the injection molding lines run about a 10-second cycle for a 17.3-gram preform, and a 17-second cycle for a 2-liter preform, says Jan Kapp, director of blow molding.

“With our injection molding, because of the cycle times and the cavitation, we have to be about one month ahead of what we are planning to blow on the bottle line,” she says.

The canning line fills 8-, 12- and 16-ounce cans. Similar to the other lines, canning speeds depend on the product being run, however, cans generally are filled at speeds of 700 to 1,080 cans a minute, Foster says.

Daily reports show the facility’s inventory levels and demand from other distribution centers and salespeople. From this, the staff can arrange for raw materials to be delivered for production. After products are filled and sealed, they’re placed in shell cases or packed in boxes, palletized and moved to the plant’s warehouse for storage. Slightly smaller than the production portion of the building, the 120,000-square-foot warehouse operates on a five-day inventory.

Although the Ogden facility is a well-oiled machine, Admiral Beverage continues to look for updates that will make its operations more efficient and cost-effective. One of the plant’s newest additions is a registered shrinkwrap bundler. Previously, the company could only make use of clear shrinkwrap. With the new equipment, it can use decorated shrinkwrap packaging on its cans or bottles, enabling greater flexibility and a better ability to suit customer needs, Foster says.

Updates in Wyoming

Admiral Beverage’s Worland facility has seen many changes since its inception in 1947. Because the business operates in nine states and offers nearly 1,600 SKUs, the company requires a lot of square footage. As the company acquired franchises and moved from one production line to five, it added more and more space to its Worland plant, eventually ending up at 120,000 square feet — for now. There still is room for expansion; however, there is not a need currently because the company is maximizing its space with equipment and taking advantage of its vertical room.

This winter, the facility introduced a new bag-in-box filler that will produce two to three times as many boxes a minute, says Dave Willard, vice president of production. Previously, the machine produced four to five boxes a minute; now, it produces about 12 boxes a minute.

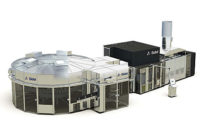

Additionally, the Worland facility introduced a new blow-molding machine to its bottle line. The company’s existing linear blow molder continues to be used for 1-liter and 2-liter bottles, and the new rotary blow molder handles all other sizes. When the company used only the linear blow molder, it struggled to keep up with the production cycle. Because it could not mold bottles fast enough, the company had to store the bottles in totes in the warehouse.

After six years of blow molding, it introduced the rotary blow molder to increase efficiency, save space in the warehouse and offer a seamless production cycle from start to finish, Willard says. The linear blow molder produces about 8,000 bottles an hour, while the rotary blow molder manufactures more than twice that amount at 28,000 to 32,000 bottles an hour.

In total, the Worland plant has two blow-molding lines, two bottle lines, two can lines and one bag-in-box line. One of the company’s bottle lines is for carbonated soft drinks, while the other is specifically for bottled water, such as Admiral Beverage’s own Aquavista brand. The CSD bottle line runs 16.9-ounce, 20-ounce, 1-liter and 2-liter PET bottles, along with 10-ounce glass bottles, at an average of 350 bottles a minute. The water filling line runs 16.9-ounce, 20-ounce and

1-liter bottles at about 400 bottles a minute. The can lines both fill 12-ounce cans exclusively at around 1,000 cans a minute.

To get the cases of products to where they need to be, the company uses its transport division to arrange delivery to and from its 40 distribution centers, and carriers for one-way orders. Such a large territory calls for a large fleet: Admiral Beverage maintains a fleet of 1,600 vehicles. And getting product orders to customers is no small task when one of your territories is Alaska.

To ship the DPS brands to Alaska, where it is the exclusive distributor of the brands, products are put on a carrier and shipped to a port in Seattle, Willard explains. From there, the products are loaded into containers and put on a barge for transport to Whittier, Alaska. Once the shipment is offloaded, it’s put onto trains, then loaded on trucks headed for Anchorage. From there, it’s shipped to customers throughout the state, which oftentimes includes a small plane ride to the outlying areas of the state.

Warehouse technologies

In addition to investing in racking in all of its warehouses, Admiral Beverage is streamlining its operations with a voice-operated picking system and tracking software.

Last year, the company began incorporating a new voice-operated picking system in its warehouses and distribution centers. This year, it expects to expand the system to most, if not all, of its relevant facilities, the company says. The system transfers orders to handheld units that tell the loaders exactly what to put on the pallet as they travel through the aisles of a warehouse, explains Patrick Reed, senior vice president of sales and field marketing.

“It’s all automated, and they will be able to pick anywhere between 330 and 400 cases per hour with the pick system versus the conventional system, [which allows] 220 to 250 cases at the most,” he says. “It enhances your picking system by over 100 cases a night, which cuts down a lot of your manpower and labor costs.”

It will create efficiencies, better working conditions and safety, adds Tom Taylor, senior vice president and chief operating officer of Admiral Beverage. Without the system, employees pick items by hand according to a load sheet. The voice-pick system walks them through the entire process.

“Plus, it improves your efficiencies to your customer,” says Kelly Clay, the company’s president and chief executive officer. “Your miss-picks are virtually eliminated, and it allows for many fewer out-of-stocks. It’s a much more efficient way to operate the warehouse and your delivery system. … And it makes the employee’s job easier.”

The company also is in the final stages of a complete information technology overhaul, Taylor says.

“We’ve been at it for a few years and the outcome should be more transfer of orders wirelessly,” he says. “So our salesmen can send that information into their sales center and begin the dispatch process. On the warehousing side, we’re going to have more real-time, accurate information electronically versus by hand. We’re looking for a lot of upside from the new system.”

AJ Jenness, Worland plant manager, explains that the new software program will have the ability to track a product in real time from production to delivery. The system tags cases or pallets with bar codes, which allows Admiral Beverage employees to scan the products into the system for tracking.

“At any point in time, if [someone] wanted to check to see how much Pepsi was on the floor, he would know immediately, and then he could also look and see where it’s been, who’s bought it, if it’s on a truck, etc.,” Jenness explains.

“That also helps us track dollars as well,” he adds. “[We can track] the amount of product that’s going into a bottle or the amount of product or raw materials that are going into the number of cases we’re doing, and then the number of pallets we’re doing and truckloads.”

The system also will be helpful for new releases, Jenness says. “Then when Kelly says, ‘I want to sell a new product and it’s going to be in this bottle, have this label, etc.,’ we will then be able to look at [the system] by adding all these different pieces together and give him an almost instantaneous answer as to what our floor costs would be for that particular product.”

Without this software, employees must track everything on paper, which is much more time consuming, Willard adds.

Though incorporating new equipment and software into its facilities is no small task, it’s part of what has helped Admiral Beverage become a trendsetter. As a result, it’s reaping the benefits. BI

| Cleaning up |

|

Sanitation has to be top of mind for the food and beverage industry. But that doesn’t mean it cannot be cost-efficient. Admiral Beverage was one of the first PepsiCo bottlers to adapt a new sanitizing process for its production equipment, the company says. Instead of transporting and storing hazardous chemicals, the system uses a detergent and a sanitizing chemical, which is produced on-site and requires only salt, water and power to operate. After purchasing the technology, all that Admiral Beverage needs to keep in stock is salt. In addition to saving money on supplies, the system saves on labor, water, contact time and rinse-out time, says AJ Jenness, Worland, Wyo., plant manager. “We aren’t bringing in harsh chemicals, we aren’t bringing in a whole bunch of totes or recyclable products that we’ve got to worry about cleaning out,” he says. “Pretty much the long and short of it is it helps us not only with our sanitizing, but the excess that is created — because the machine runs all the time — we run down our drain and it helps us with our [biochemical oxygen demand] and our [total suspended solids], which is our sewer system, so we don’t have such a high loading on the city’s system as well.” The system’s implementation has attracted attention from other companies, says Dave Willard, vice president of production. “We’ve had a number of calls since we put [the system] in,” Willard says. “We do a lot of things before anybody else. Especially if it’s going to affect our bottom dollar and it works well and creates less labor.” BI |

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!