Home » Keywords: » AGVs (automated guided vehicles)

Items Tagged with 'AGVs (automated guided vehicles)'

ARTICLES

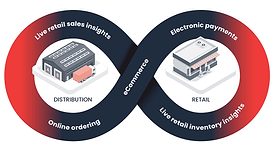

Market Insights

Technology advancements streamline beverage distribution

Read More

Warehouse

Automated guided vehicles benefits expand during pandemic

Advancements help AGVs operate more efficiently, safely in beverage warehouses

August 5, 2020

Beverage plants interface robotics and automation

Robotic arms improve supply chain processing

October 21, 2019

AGVs maximize production, ROI for warehouses

Suppliers introduce new AGVs to beverage market

August 23, 2019

Advanced technology drives automated guided vehicles

Speed, cost savings among benefits of infrastructure-free navigation

August 15, 2017

AGVs proliferate as warehouse automation grows in beverage industry

MHI to expand ProMat 2017 to include autonomous vehicle solution center

August 15, 2016

Clearing a path for Automated Guided Vehicles

Automated guided vehicles demonstrate value, efficiency and safety

August 15, 2012

Elevate your expertise in the beverage marketplace with unparalleled insights and connections.

Join thousands of beverage professionals today. Shouldn’t you know what they know?

JOIN NOW!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing