Articles by Tom Kelley

Protect your fleet through driver training, scheduled vehicle maintenance

Read More

Mid-America Trucking Show focuses on safety, efficiency

Trucking companies highlight telematics solutions

May 16, 2014

Fleet managers turn to route optimization to cut delivery costs

Route optimization, tracking software boost distribution efficiency

March 14, 2014

The 2013 State of the Beverage Fleet Industry

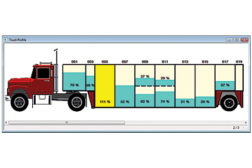

Results reflect shift to end-load trailers

February 14, 2014

New Belgium’s brewery-direct fleet goes hybrid

Craft brewer blends environmental stewardship with local distribution

January 15, 2014

Best Fleet Graphics of 2013

Leading fleets use innovative graphics to stand out

October 16, 2013

Top fleet manager offers thoughts on alternative fuels

A Q&A with Silver Eagle Distributors’ Ed Pritchard

September 16, 2013

Elevate your expertise in the beverage marketplace with unparalleled insights and connections.

Join thousands of beverage professionals today. Shouldn’t you know what they know?

JOIN NOW!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing