Packaging Equipment

Experts point to AI for the future of new product development

Consumer-centric approach allows brands to create successful, efficient products

August 31, 2022

Packaging Equipment

Digital printing, user-friendly label equipment support circular economy

Packaging evolutions prompt advancements for labeling equipment

August 19, 2022

Packaging Equipment

Advanced coding technologies offer beverage operations optimal solutions

Artificial intelligence, augmented reality offer potential to streamline coding, marking

July 29, 2022

Packaging Equipment

Beverage inspection advances improve integrity

Automation offers accurate picture for beverage operations

June 29, 2022

Filling technology combining key elements to streamline beverage operations

Cold aseptic filling, improved sanitation methods driving filling equipment innovations

March 17, 2022

Packaging Equipment

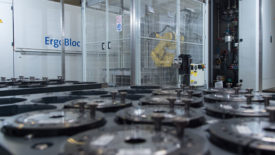

Case packing, wrapping equipment offers quick product changeovers, maximizes efficiencies

Sustainability becoming greater focus of packing machinery

February 23, 2022

Elevate your expertise in the beverage marketplace with unparalleled insights and connections.

Join thousands of beverage professionals today. Shouldn’t you know what they know?

JOIN NOW!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing