Packaging Equipment

Filler equipment demands flexibility, fast changeovers

New product reduces total package oxygen in beer-bottling lines

April 15, 2016

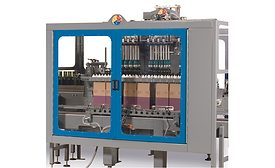

Packaging trends drive flexibility in case packers and wrappers

Beverage equipment suppliers offer flexible, fast case packers and wrappers

March 15, 2016

Can filling, seaming equipment need grows as packaging trends move toward cans

Craft beer industry, varying can styles drive innovation

January 15, 2016

InterBev Process teams with FPSA and IDFA shows

Tradeshow features beverage product innovations, processing and packaging technologies

November 16, 2015

Plastic bottle manufacturers address flexibility, sustainability

Lightweighting, sustainability drive plastic bottle manufacturing

November 16, 2015

Beverage-makers seek reliable stretch-wrapping equipment

Automation helps advance stretch wrappers capabilities

October 16, 2015

Pack Expo co-locates with Pharma Expo

ISBT hosts reception at The Beverage Cooler Lounge

September 16, 2015

Choosing codes, improving production

Special inks, digital solutions deliver goods

September 16, 2015

Elevate your expertise in the beverage marketplace with unparalleled insights and connections.

Join thousands of beverage professionals today. Shouldn’t you know what they know?

JOIN NOW!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing