Home » coding

Articles Tagged with ''coding''

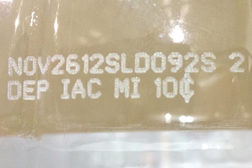

Coding equipment meets marketing demands for beverage manufacturers

Laser coding capabilities catch up to continuous inkjet coders

August 15, 2014

Coding equipment hitting on all fronts

SKU proliferation influencing technology

September 16, 2013

Coding technology addresses SKU proliferation, reliability

SKU proliferation, reliability influence coding technology

September 17, 2012

Coding technology addresses flexibility

Container shapes, speed affect machinery designs

September 15, 2011

Elevate your expertise in the beverage marketplace with unparalleled insights and connections.

Join thousands of beverage professionals today. Shouldn’t you know what they know?

JOIN NOW!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing