Home » plastic bottle manufacturing

Articles Tagged with ''plastic bottle manufacturing''

Changeover efficacy vital to accommodate new products, packaging

Read More

Packaging Equipment

Plastic bottling systems keep pace with sustainable packaging trends

Growing interest in rPET bottles highlights importance of inspection equipment

October 30, 2023

Packaging Equipment

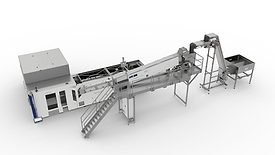

Plastic bottle manufacturing equipment addresses energy usage, diagnostics

Self-regulating practices minimize need for human intervention with preforms

October 18, 2022

Packaging Equipment

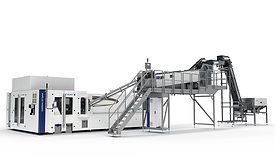

Plastic bottle manufacturing addresses sustainability, digitalization

Equipment suppliers designing equipment to handle increased usage of PCR materials

October 20, 2021

Sidel introduces StarLITE HPC base to increase stability of PET, rPET containers

Oval shape provides better stability on conveyors

July 27, 2021

Packaging Equipment

Plastic bottles adapt to today’s beverage trends

Flexible machinery necessary to support beverage delivery

October 20, 2020

Frigel Eco Dry System debuts cooling systems for plastics industry

Patented cooler saves water usage of 95 percent

November 25, 2019

Elevate your expertise in the beverage marketplace with unparalleled insights and connections.

Join thousands of beverage professionals today. Shouldn’t you know what they know?

JOIN NOW!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing