Home » automated storage and retrieval systems (ASRS)

Articles Tagged with ''automated storage and retrieval systems (ASRS)''

Pallet rack system provides 250 percent greater frontal impact strength

Read More

Steel King offers drive-in and drive-thru racking system

Users can store up to 75 percent more pallets

August 17, 2018

Storage systems accommodate growing facilities, SKU proliferation

Automated storage systems gain popularity within beverage facilities

February 22, 2018

Creativity, automation propelling warehouse storage solutions

SKU proliferation, eCommerce impacting beverage warehouses

February 15, 2017

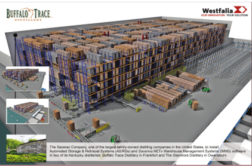

Automation supports beer, wine and spirits operations

Westfalia Technologies shows benefits of AS/RS systems

December 15, 2015

What beverage distributors should consider before automating a warehouse

Defined tasks crucial for automation evaluations

March 16, 2015

AS/RS tackle storage challenges presented by SKU proliferation

Automated systems deliver complex orders at high speeds

February 16, 2015

Sazerac to install AS/RS systems in two distilleries

Sazerac becomes first U.S. spirits producer to use AS/RS technology

May 1, 2014

New packaging material incorporates flavor into functionality

Inks, on-premise beverage machines give drinks new look and fresh appeal

April 16, 2014

Warehouses turning to automation for storage needs

SKU proliferation demands enhanced storage solutions

February 14, 2014

Elevate your expertise in the beverage marketplace with unparalleled insights and connections.

Join thousands of beverage professionals today. Shouldn’t you know what they know?

JOIN NOW!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing